"Configuring & Consultation on setting up of the entire project, from its Blue Print to regular production - This at a fractional Project Cost in comparison to traditional project build

Advantage

- A well-engineered -cost effective manufacturing infrastructure is a strategic asset that directly impacts product economics.

- By modularizing the design of Manufacturing Sequence and the design of injection Moulding Machines, capital investment costs can be significantly reduced.

- Standardized components and scalable production systems lower upfront tooling and setup expenses.

- This modular approach accelerates time-to-market while maintaining high build quality and reliability.

- Reduced capital expenditure means quicker ROI and less financial strain on emerging enterprises.

- Lower production costs per unit enhance profitability without compromising performance or durability.

- Efficient infrastructure enables lean operations, minimizing waste and optimizing resource allocation.

- With reduced investment and controlled operating costs, businesses can price competitively and grow sustainably.

- The synergy of precision engineering and economic design fosters resilience in volatile markets.

- Ultimately, it empowers manufacturers to build high-value products while maximizing margins and minimizing risk.

Part -1

Configuring and Setting up a test module.

This involves reverse engineering and configuring complete process protocol from concept to test model.

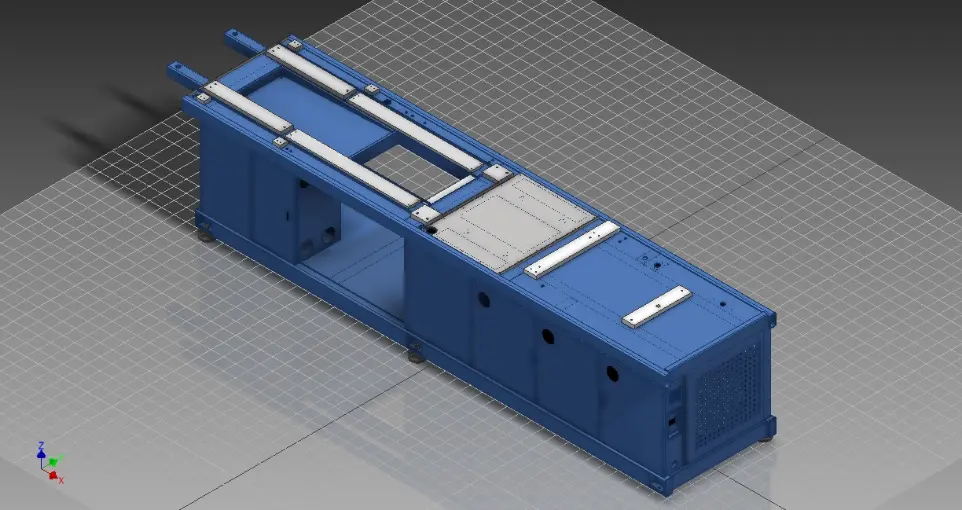

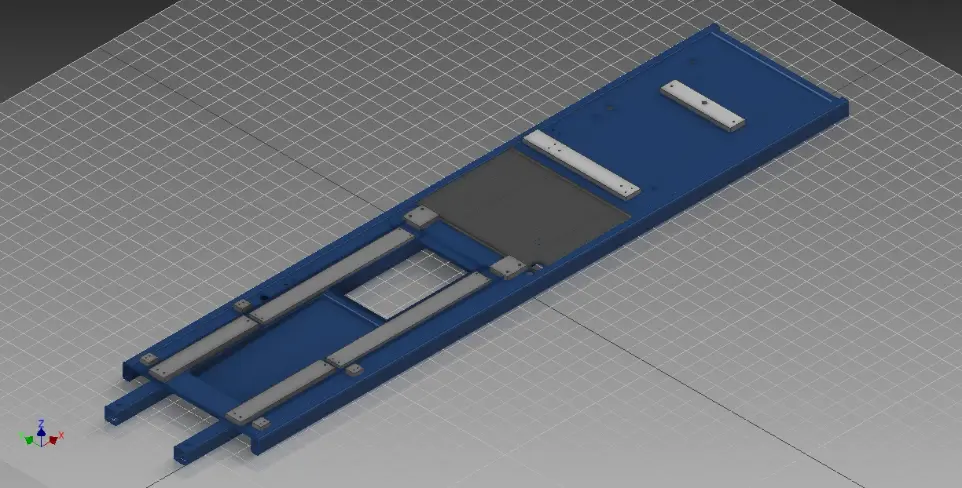

Base Structure 3D Modelling

3D modelling of a machine base structure prior to manufacturing enables precise visualization and design validation. It helps identify potential structural flaws, optimize material usage, and ensure compatibility with other components. This process streamlines fabrication, reduces errors, and accelerates production timelines.

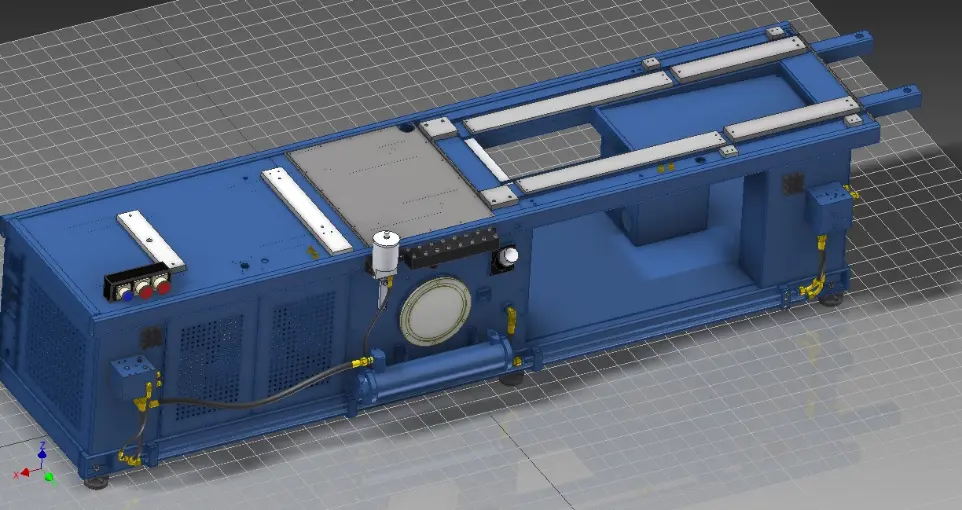

Base Structure 3D Model - Acessories Assembly

Generating a 3D model of machine base accessories assembly, before manufacturing, ensures precise integration of all components. It allows engineers to visualize spatial relationships, check for interference, and refine mounting points. Digital assembly modeling streamlines design iterations, reducing costly errors during fabrication. This proactive approach enhances efficiency, accuracy, and overall system reliability.

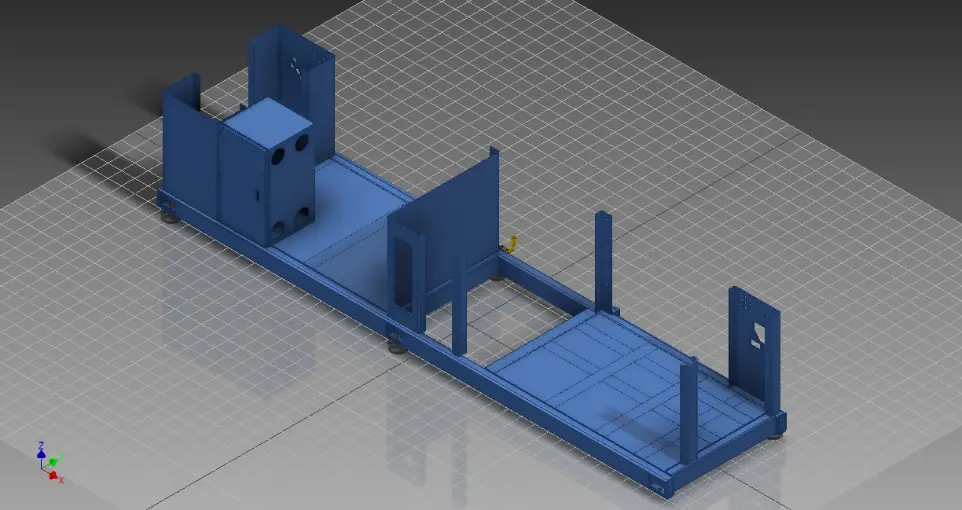

Fabrication Sequence - Base Platform

Creating a virtual 3D build of the machine base platform section allows engineers to visualize structural integrity before physical fabrication. It enables precise alignment of mounting zones, load paths, and accessory interfaces in a simulated environment. This digital approach reduces design errors, enhances collaboration, and speeds up iteration cycles. Ultimately, it leads to cost-effective manufacturing with improved performance and reliability.

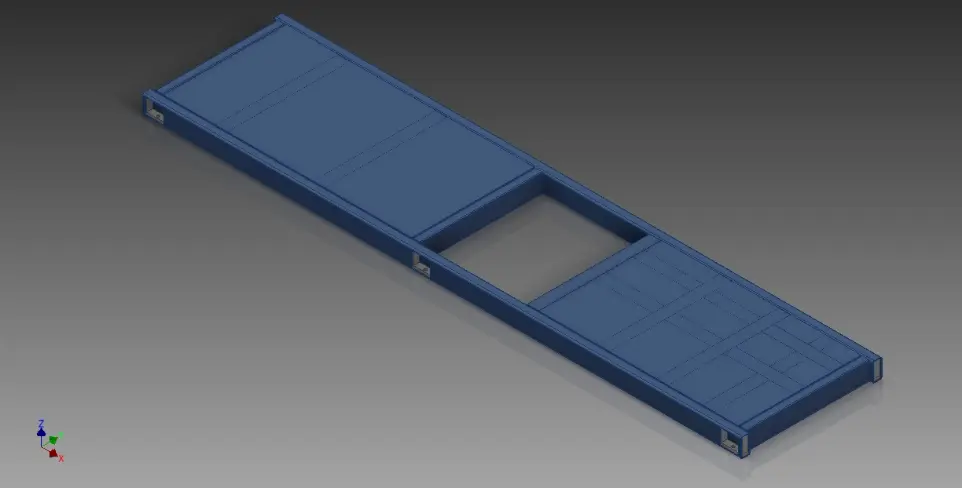

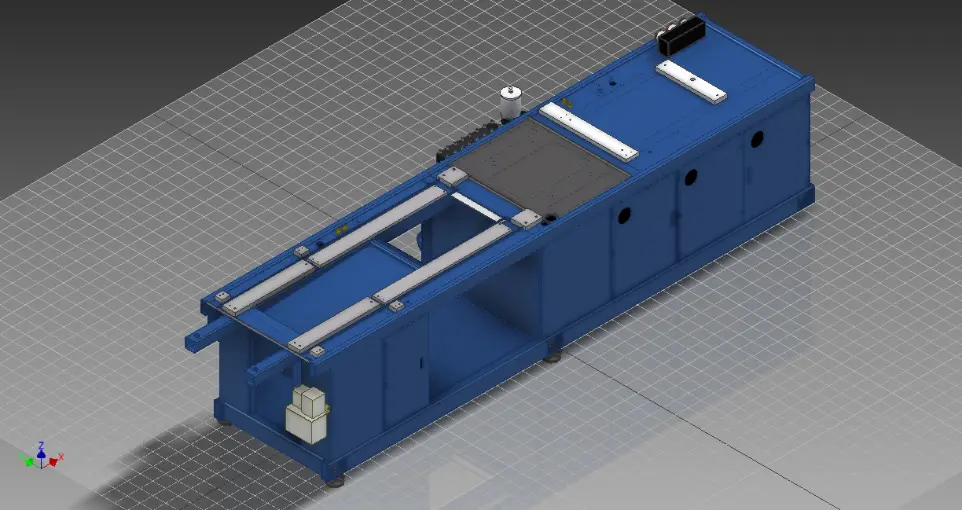

Fabrication Sequence - Top Platform

Virtual 3D modelling of the machine's top platform section enables precise design of mounting zones, access points, and component interfaces. It allows engineers to simulate operational dynamics, ensuring optimal layout and load distribution. This digital build helps detect spatial conflicts early, reducing rework and fabrication delays. Ultimately, it enhances design accuracy, speeds up prototyping, and improves overall system integration.

Fabrication Sequence - Midsection Elements Sequential Assembly

Virtual 3D modelling of machine midsection elements enables precise visualization of internal structures and component placement. Sequential assembly in a digital environment ensures logical build order, reducing clashes and improving workflow efficiency. It allows for early detection of design flaws, alignment issues, and accessibility constraints. This approach enhances assembly accuracy, shortens production time, and supports smoother integration with top and base sections.

Fabrication Sequence - Midsection Accessories Assembly Validation

Virtual 3D modelling of machine midsection accessories enables precise placement and alignment before physical assembly. It facilitates early validation of fit, function, and connectivity across complex components. Engineers can simulate operational scenarios to detect clashes or inefficiencies in real time. This approach reduces prototyping costs, improves design accuracy, and accelerates production readiness.

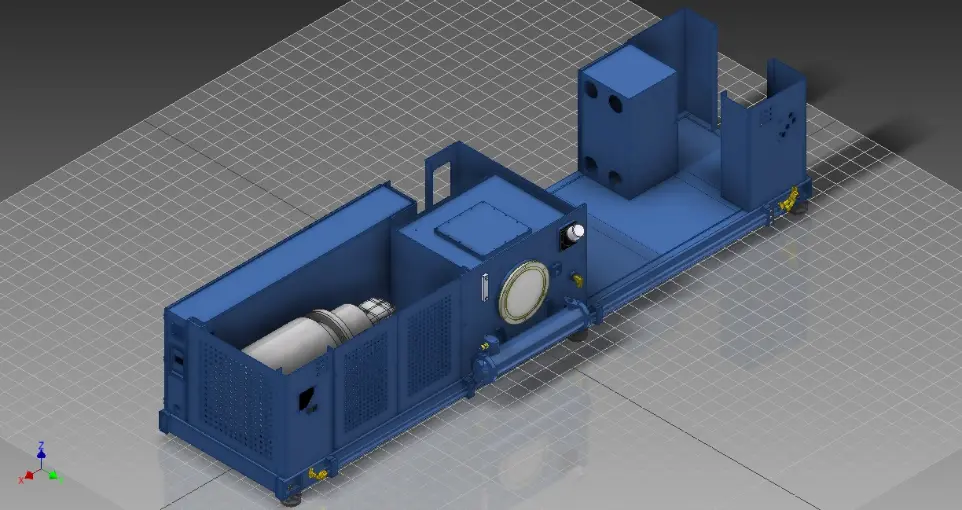

Fabrication Sequence - Base Structure Assembly

Final virtual assembly of the machine base structure in a 3D environment ensures seamless integration of all components with precise alignment. It enables thorough validation of structural integrity, load distribution, and mounting accuracy before fabrication. Engineers can simulate real-world conditions to identify potential issues and optimize design performance. This digital approach minimizes production errors, reduces costs, and accelerates time-to-market.

Test Model - Fabrication Build - Base Platform Completion

Real-time testing of the model ensures functional accuracy and immediate feedback for design refinement. Fabrication build translates validated designs into physical components with precision and speed. Base platform completion marks the integration of structural elements, readying the system for full assembly. This streamlined workflow enhances efficiency, reduces rework, and accelerates deployment timelines.

View

View

View

Test Model - Fabrication Build - Top Platform Completion

Real-time testing of the top platform model ensures precise validation of design intent and operational functionality. Fabrication build translates the refined digital model into a robust physical structure with accurate tolerances. Top platform completion integrates all mounting features and access zones, readying it for final assembly. This streamlined process boosts production efficiency, minimizes errors, and ensures optimal system performance.

View

View

View

Test Model - Fabrication Build - Installation of Middle section elements.

Real-time test modeling validates structural integrity and performance before fabrication begins. Fabrication build transforms digital blueprints into precision-engineered components for seamless integration. Installation of middle section elements demands exact alignment to ensure load distribution and system stability. Together, these phases create a synchronized workflow that accelerates deployment and minimizes rework.

Test Model - Fabrication Build - Accessories & Supporting elements assembly Validation

Real-time test modeling ensures all accessory and support designs meet operational standards before build. Fabrication build converts validated models into tangible components with precision and durability. Assembly of accessories and supporting elements is executed with strict alignment and integration protocols. Final validation confirms structural coherence, functional readiness, and compliance with design intent.

Test Model - Fabrication Build - Complete Base Structure final assembly and validation

Real-time test modeling ensures the base structure meets all load and design criteria before fabrication. Fabrication build translates engineered specs into durable components with high structural fidelity. Complete base structure assembly integrates all foundational elements with precision and alignment. Final validation confirms stability, dimensional accuracy, and readiness for upper-level integration.

Test Model - Fabrication Build - Base Structure finish

Base structure finishing involves surface treatments, alignment checks, and integration of final features. This stage guarantees readiness for full assembly, enhancing durability, accuracy, and operational reliability.

Test Model - Fabrication Build - Base Structure Critical Component Installation Validation

Base structure undergoes meticulous alignment for seamless integration of vital components. Installation validation confirms operational readiness, safety compliance, and structural reliability.

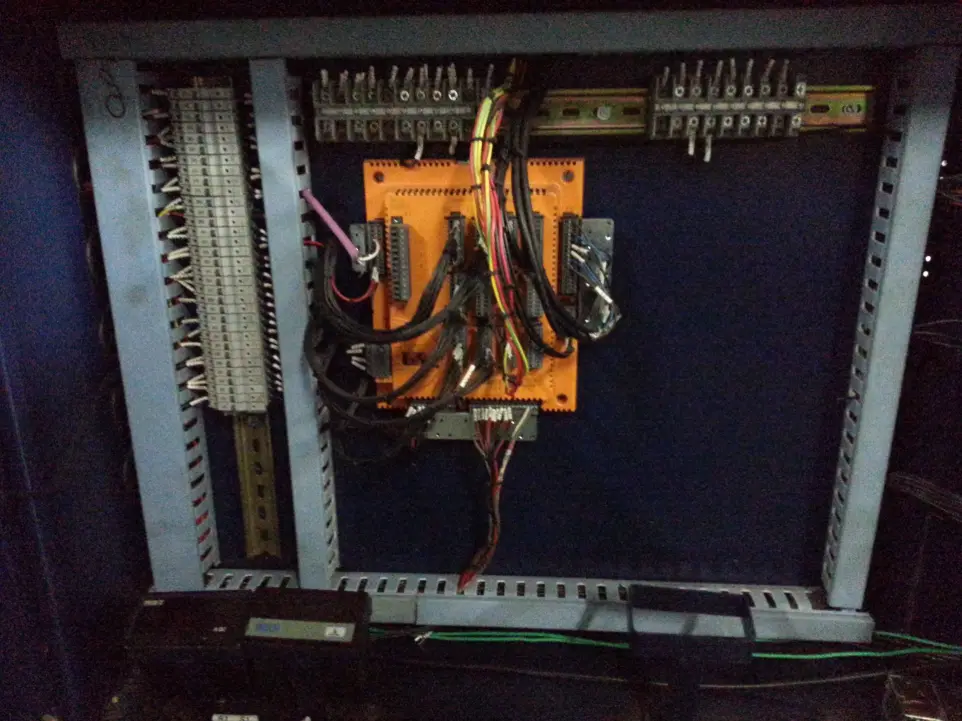

Test Model - Fabrication Build - Base Structure - Electrical Pannel Installation Validation

Structural and fitment checks ensure mounting accuracy, load support, and alignment with design specs. Electrical panel installation is validated for secure fastening, cable routing, and thermal clearance. Final inspection confirms operational safety, compliance, and seamless integration into the system.

Test Model - Fabrication Build - Base Structure - Oil Tank Assembly Installation Validation

Its ease of integration enhances design flexibility, enabling customization across different machine models.

Test Model - Fabrication Build - Base Structure - Display Pannel Installation Validation

Real-time test modeling ensures the base structure is engineered to support display panel integration. Structural and fitment validation confirms precise alignment, secure mounting, and vibration resistance. Final checks verify visual accessibility, cable routing, and compliance with installation standards.

Test Model - Complete Machine Assembly Validation

Final assembly integrates mechanical, electrical, hydraulic, Electronics and structural elements into a cohesive operational unit.

Test Model - Fabricated Base Structure - Pre Paint Preparation

Pre-paint preparation includes cleaning, sanding, and applying primer to enhance adhesion and durability. This stage ensures a smooth, defect-free surface, improving corrosion resistance and final appearance.

Test Model - Fabricated Base Structure - Intermediate Surface Correction

Intermediate surface correction includes grinding, filling, and smoothing to ensure uniformity and paint adhesion. This step enhances structural aesthetics, prevents coating defects, and ensures long-term durability.

Test Model - Fabricated Base Structure - Final Paint finish.

The base structure is engineered for strength and precision, forming the foundation for all subsequent treatments. Final paint protective coating seals the surface, providing corrosion resistance, durability, and a polished aesthetic.

Test Model - Fabricated Base Structure - Final Paint finish checks.

Final paint finish checks ensure flawless coating, verifying uniformity, adhesion, and aesthetic consistency.

Test Model - Fabricated Base Structure - Validation of color aesthetics in reference to add on elements such as covers and accessories.

Color aesthetics are validated against add-on elements like covers and accessories to maintain visual harmony. This step involves comparing shades, finishes, and textures to ensure cohesive integration across components. Final approval confirms that the assembled unit delivers both structural integrity and refined visual appeal.

Test Model - Sourcing of critical component from top Indian Brands.

Controller ~ B&R, Beckhoff, KEBA and such..

Electricals ~ Siemens, Schnider, Eaton, Polycab, Omron, and such..

Hydraulics ~ Eaton, Yuken, Rexroth, HNC and such..

Power Pack ~ Siemens, ABB, Bharat Bijlee, and such..

Drive System ~ Siemens, ABB, KEB, Yashkawa and such..

Tie-Bar Assembly ~ Special alloy make from reputed brands in Ahmedabad and Mumbai.

Hydraulic Cylinder ~ Yuken, Eaton and such...

Pneumatic Components - Festo and such...

Screw Barrel Assembly ~ Option of top brands in Ahmedabad and Mumbai.

Special Alloy Steel Casting Platens ~ Import -

Special Alloy Steel Casting Injection Base section ~ Import

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Final assembly integrates mechanical, electrical, hydraulic, Electronics and structural elements into a cohesive operational unit. A structured test run validates system performance, safety protocols, and functional reliability under simulated conditions. Successful validation confirms readiness for deployment, minimizing risks and ensuring optimal efficiency.

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Rear Side view.

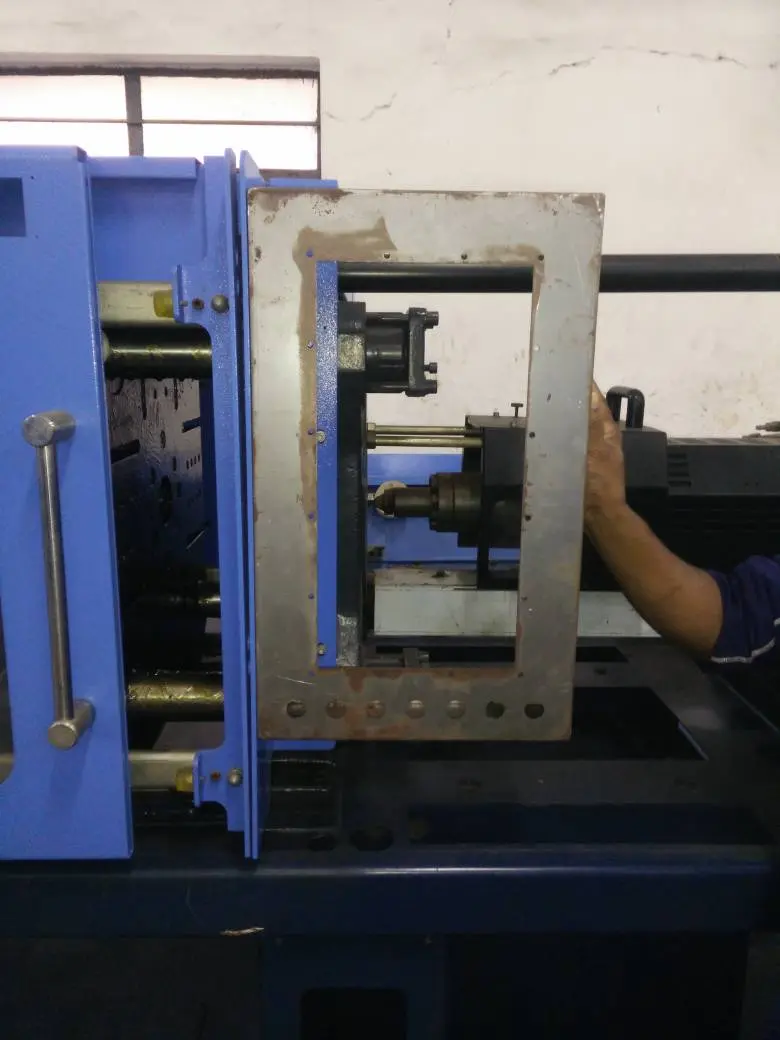

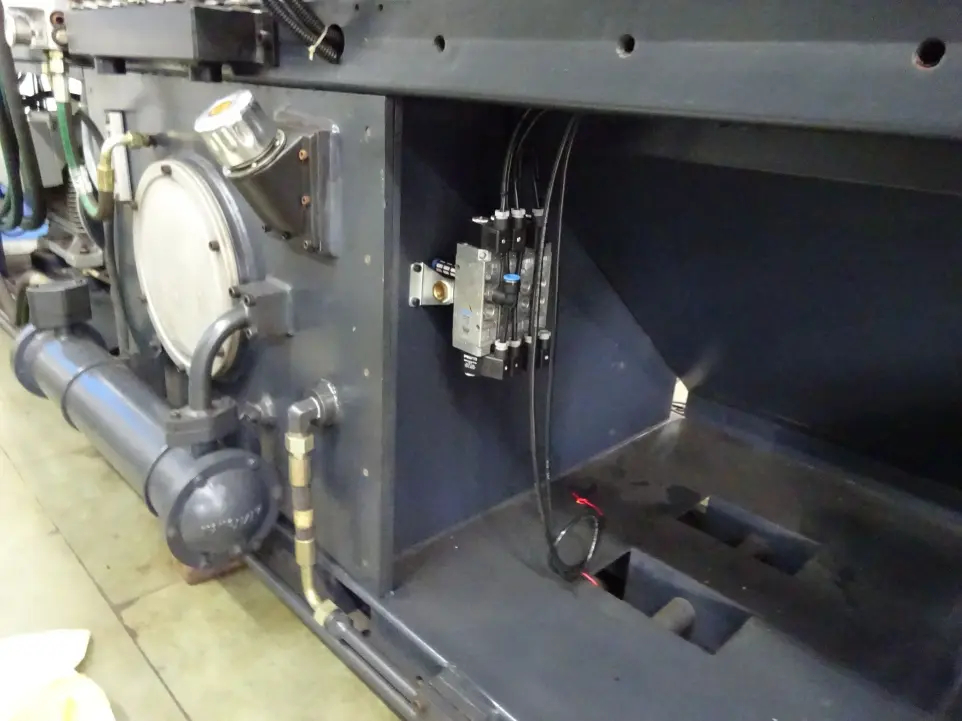

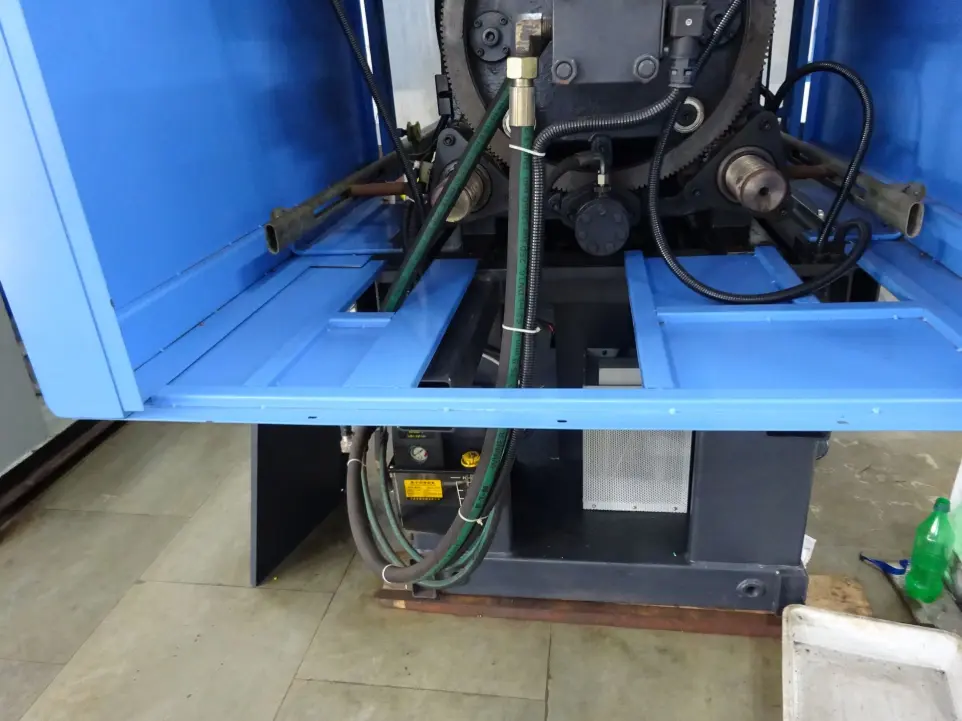

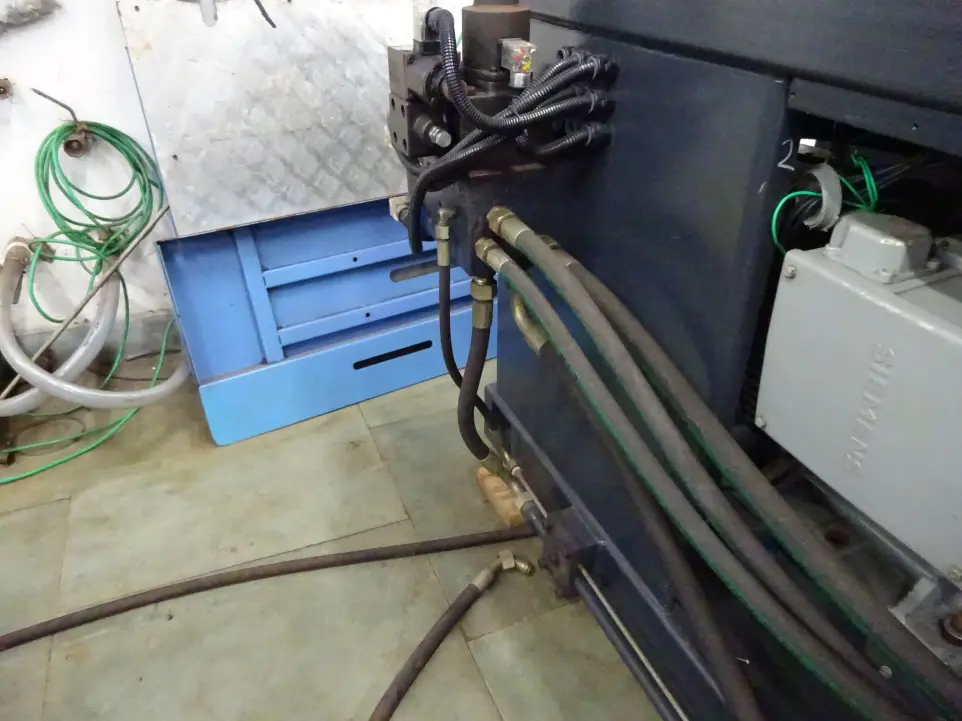

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Elements Detailing.

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Elements Detailing.

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Elements Detailing.

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Elements Detailing.

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Elements Detailing.

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Elements Detailing.

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Elements Detailing.

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Elements Detailing.

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Elements Detailing.

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Elements Detailing.

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Elements Detailing.

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Elements Detailing.

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Elements Detailing.

Test Model - Final Assembly - Validation of complete assembly with structured test run.

Elements Detailing.

Seamless Transition to Regular Production

Regular Production - Base Fabrication in batches

Regular production of the base structure is executed in controlled batches to maintain consistency and quality. Batch fabrication allows streamlined workflow, efficient resource allocation, and predictable output timelines. Each batch undergoes standardized checks for dimensional accuracy, weld integrity, and surface finish. This method ensures scalable manufacturing while minimizing defects and optimizing production efficiency.

Regular Production - Base Fabrication in batches

View

Regular Production - Base Structure Paint Job in batches

Regular production of base structure paint jobs is executed in batches to ensure consistency in finish and color tone. Each batch undergoes surface preparation, primer application, and controlled paint layering for durability. Quality checks are performed on every unit to validate adhesion, uniformity, and resistance to wear. Batch processing streamlines workflow, reduces waste, and maintains high aesthetic and protective standards.

Regular Production - Base Structure Paint Job in batches

View

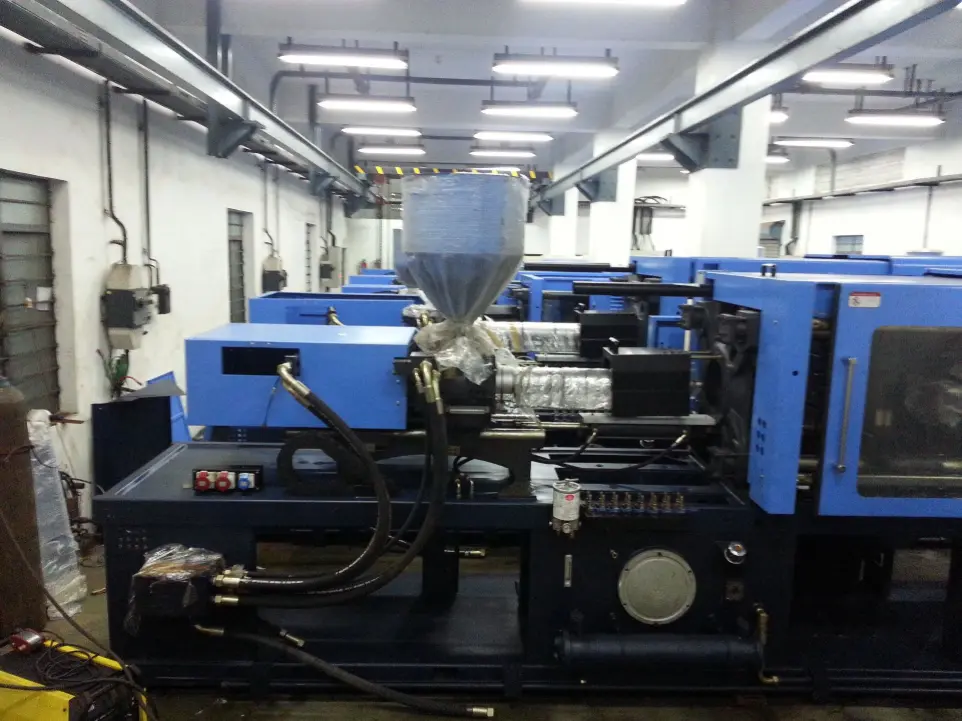

Regular Production - Machine Primary Assembly in batches

Regular production of machine assembly in batches ensures streamlined workflow and consistent build quality. Batch-wise assembly allows efficient resource planning, reduced downtime, and faster turnaround. Each unit undergoes standardized checks for alignment, connectivity, and operational readiness. This method supports scalable manufacturing while maintaining precision and reliability across all builds.

Regular Production - Machine Primary Assembly in batches

View

Regular Production - Machine Primary Assembly in batches

View

Regular Production - Machine Primary Assembly in batches

View

Regular Production - Machine Final Assembly in batches

Regular production of machines, final assembly in batches ensures consistent quality and streamlined operations. Each batch integrates all subsystems—mechanical, electrical, and control units—with precision and care. Standardized validation checks confirm alignment, functionality, and compliance with design specifications. This batch-wise approach boosts efficiency, reduces errors, and supports scalable delivery timelines

Regular Production - Machine Final Assembly in batches

View

Regular Production - Machine Final Assembly in batches

View

Regular Production - Machine Final Assembly in batches

View

Regular Production - Machine Final Assembly in batches

View

Regular Production - Machine Final Assembly in batches

View

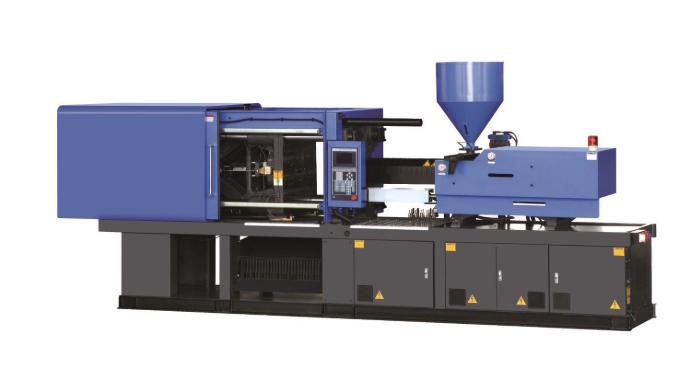

Machine Model - 110 Tons

View

Machine Model - 130 Tons

View

Machine Model - 180 Tons

Product Running : 350 ml Round Food Container.

Specification: Thin wall Container with 0.45mm wall thickness.

Cycle Time : 4sec to 4.2sec.

Standard Machine without any add on for such product. Running extremely fast cycle

Advantage : Substantial saving in capital cost as there are no requirement for specil fast cycle customization.

180 Ton & 130 Ton

Machine Model - 240 Tons

View

Machine Model - 280 Tons

View

Machine Model - 350 Tons

View

View